Top 10 Tips for Effective Crane Lifting Techniques and Safety Best Practices

Crane lifting crane techniques play a critical role in ensuring safety and efficiency at construction sites and industrial lifting operations. With the growing reliance on cranes for heavy lifting, understanding the best practices for crane lifting crane operations becomes essential. The importance of implementing effective crane lifting techniques cannot be overstated, as it not only enhances productivity but also helps prevent accidents and injuries that can result from improper handling of loads.

In this guide, we will explore the top 10 tips for effective crane lifting crane techniques, focusing on safety and operational excellence. These practices encompass comprehensive planning, proper equipment selection, and rigorous safety protocols that must be adhered to throughout the lifting process. Whether you are an experienced operator or new to the field, this information is vital to ensuring that every lift is performed smoothly and securely, safeguarding personnel and property alike. By embracing these techniques, you will contribute to a culture of safety that permeates the worksite, ultimately leading to more successful and less hazardous lifting operations.

Understanding the Importance of Crane Lifting Techniques and Safety

Crane lifting techniques are crucial not only for the efficiency of operations but also for ensuring the safety of personnel and equipment. According to a report by the Occupational Safety and Health Administration (OSHA), improper lifting techniques are a major cause of workplace accidents in the construction industry, contributing to nearly 34% of crane-related injuries. Therefore, understanding the importance of following strict crane lifting protocols cannot be overstated. When operators adhere to best practices, they significantly reduce the risk of accidents, which in turn lowers insurance premiums and enhances operational productivity.

Key factors in effective crane lifting include the proper assessment of load weight and center of gravity, as well as ensuring that all personnel are aware of their roles and the lifting sequence. Studies show that projects with well-implemented safety practices can experience up to a 50% decrease in accident rates. The American Society of Civil Engineers (ASCE) emphasizes that regular training and certification for crane operators contribute to better job site safety and compliance with safety regulations. In sum, investing time and resources in crane lifting techniques and safety protocols not only protects workers but also supports the overall success of construction projects.

Top 10 Tips for Effective Crane Lifting Techniques and Safety

This chart illustrates the importance of various crane lifting techniques and their respective effectiveness in ensuring safety during operations. Each technique is rated based on its contribution to overall safety and efficiency.

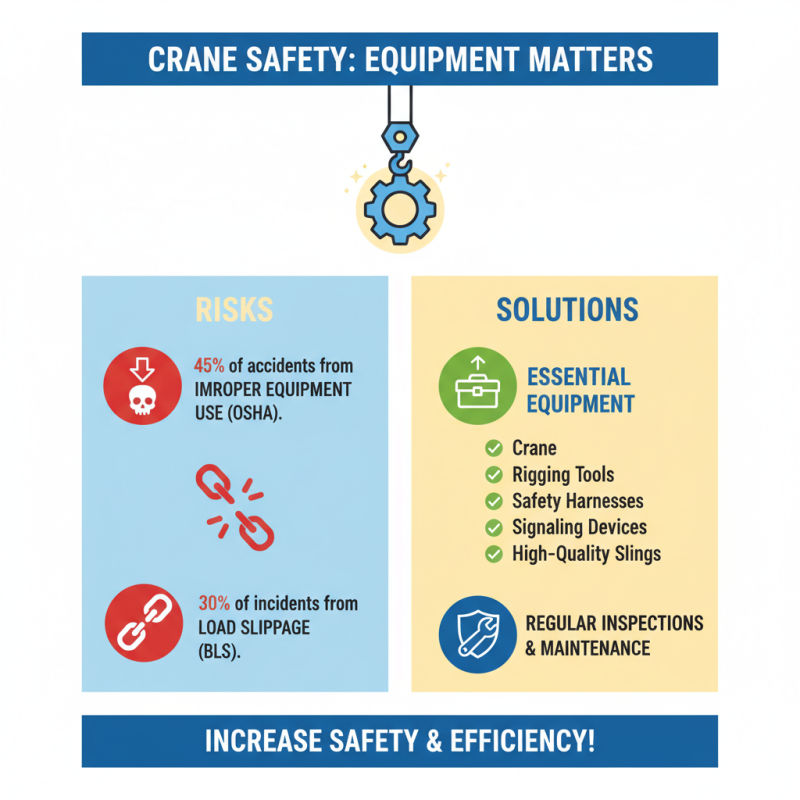

Essential Equipment for Safe Crane Operation and Maintenance

When it comes to safe crane operation and maintenance, having the right equipment is paramount. According to the Occupational Safety and Health Administration (OSHA), improper equipment usage contributes to nearly 45% of crane-related accidents. Essential equipment for crane operation includes not only the crane itself but also rigging tools, safety harnesses, and signal devices. Regular inspections and timely maintenance of these tools can significantly increase operational safety and efficiency. For instance, using high-quality slings can reduce the risk of load slippage, which accounts for approximately 30% of lifting incidents, as highlighted by the Bureau of Labor Statistics.

Additionally, investing in advanced safety technologies such as load moment indicators (LMIs) and anti-collision systems plays a crucial role in enhancing safety standards. A report from the American National Standards Institute (ANSI) indicates that cranes equipped with modern safety features reduce the likelihood of accidents by 40%. Furthermore, proper training and certification of operators are essential, as studies show that approximately 70% of crane accidents can be attributed to operator error. Therefore, ensuring that personnel are well-equipped with both the right physical tools and comprehensive knowledge is vital for proficient and safe crane operation.

Pre-Lift Planning: Assessing Load and Surrounding Conditions

Effective crane lifting techniques begin with meticulous pre-lift planning, focusing on assessing both the load and surrounding conditions. According to the National Occupational Safety and Health Administration (OSHA), approximately 45% of all crane-related accidents involve issues stemming from improper load assessment. Understanding the load's weight and center of gravity is essential to ensure a stable lift. Additionally, the American Society of Civil Engineers (ASCE) suggests that evaluating the overall structural integrity where the lift will occur can prevent unforeseen accidents, particularly in urban environments where surrounding buildings and infrastructure may pose risks.

In addition to load evaluation, environmental conditions play a critical role in crane safety. Weather conditions such as wind speed, temperature variations, and visibility can significantly impact lifting operations. The American National Standards Institute (ANSI) recommends rigorous checks for wind conditions, highlighting that lifts should be suspended when wind speeds exceed 30 mph, as gusts can lead to loss of control. Furthermore, site assessments for overhead obstacles like power lines and assessing ground stability are crucial steps that help mitigate risks. Adopting a comprehensive pre-lift strategy not only fosters a safer working environment but also enhances operational efficiency in crane operations.

Communication Protocols for Safe Crane Operations

Effective communication is essential for ensuring safety during crane operations. According to the Occupational Safety and Health Administration (OSHA), miscommunication is a leading cause of accidents in construction. It has been reported that nearly 90% of crane accidents are linked to communication failures between operators and ground personnel. Implementing a robust communication protocol can help mitigate these risks, enhancing overall safety on job sites.

Establishing clear lines of communication between all members of the lifting team is vital. This includes using standardized hand signals and radio communication to convey instructions effectively. The American National Standards Institute (ANSI) highlights the importance of pre-lift meetings, which ensure that all personnel understand their roles and responsibilities clearly. Regular training and drills, as recommended by the Crane Institute of America, can further strengthen communication practices and foster a culture of safety. By prioritizing communication, teams can better coordinate their efforts, substantially reducing the likelihood of accidents and injuries during crane operations.

Post-Lift Procedures: Inspecting Equipment and Reporting Incidents

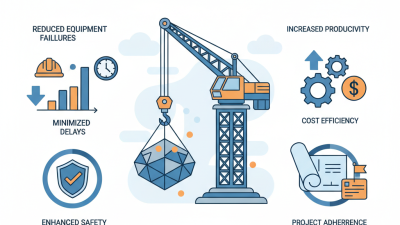

Post-lift procedures play a crucial role in maintaining safety and efficiency in crane operations. After completing a lift, it is essential to conduct a thorough inspection of all equipment used during the operation. This involves checking the crane, rigging gear, and any accessories for signs of wear, damage, or malfunction. By identifying potential issues early, operators can prevent accidents and ensure that the equipment remains in optimal working condition. Regular inspections contribute to the longevity of the equipment and minimize the risk of unexpected failures during future lifts.

In addition to equipment inspections, it is vital to establish a clear reporting procedure for any incidents that may have occurred during the lift. Whether it be near-misses or equipment anomalies, documenting these occurrences allows for a comprehensive review of safety practices and helps identify areas needing improvement. Open communication among team members regarding incidents fosters a culture of safety and encourages proactive measures to mitigate risks. By prioritizing both equipment inspections and incident reporting, crane operations can consistently adhere to safety best practices, ensuring a safer work environment for all involved.

Related Posts

-

Exploring the Future: 2025's Largest Crane Innovations and Trends

-

The Best All Terrain Crane Models for Your Heavy Lifting Needs in 2023

-

What is a Boom Crane? Understanding Its Types, Uses, and Benefits

-

10 Essential Tips for Operating a Telescopic Crane Safely and Efficiently

-

Why You Should Choose a Robust Crane for Your Heavy Lifting Needs

-

2025 How to Choose the Best All Terrain Crane for Your Project