How to Use a Crane Picking Up Crane Effectively in 2026?

In 2026, the construction industry is evolving. Effective use of equipment is paramount. One intriguing technique arises: crane picking up crane. This method optimizes workflow and enhances efficiency, yet it comes with challenges.

Adopting crane picking up crane requires strategic planning. It is essential to understand dimensions and load capacities. A clear communication line among operators is vital. Miscommunication could lead to accidents, which is a major concern. Safety measures cannot be overlooked.

While this technique offers benefits, practitioners must remain vigilant. Each lift should be evaluated carefully. Assessing site conditions and operator skills is crucial. Even with advanced technology, human error is always a factor. Reflecting on these elements can lead to better outcomes in crane operations.

Understanding Crane Types and Their Best Uses in 2026

When choosing cranes in 2026, understanding the different types available is crucial. Each type has its strengths and ideal applications. For example, tower cranes are perfect for tall buildings, providing excellent height and lifting capacity. However, they require significant setup time and space. It often takes teams pressure to get them working efficiently on site.

Mobile cranes offer flexibility, working well in various environments. They can easily maneuver around construction sites. Yet, their lifting capability is limited compared to tower cranes. You may find that relying solely on mobile cranes leads to challenges in moving heavier loads. It's key to evaluate what works best for your specific projects.

Another option, crawler cranes, are useful for rough terrain. These cranes provide stability and can handle heavy loads without sinking into the ground. Yet, they can be slower to set up and move. Understanding these nuances is essential for optimizing crane use in your operations. A thoughtful approach can reduce mistakes and delays, leading to improved project outcomes.

Key Safety Measures for Crane Operations in 2026

Safety is paramount in crane operations during 2026. Operators must prioritize understanding load limits. Overloading can lead to catastrophic failures. Regular inspections of crane components, including cables and hooks, are crucial. Any signs of wear should be addressed immediately. A small crack can lead to a big disaster.

Training for operators needs to be ongoing. New techniques emerge, and staying updated is essential. Workers should practice communication skills, especially in noisy environments. Hand signals must be clear and understood by all team members. A moment's distraction can result in serious injuries.

Weather conditions play a significant role in crane safety. Operators should monitor forecasts closely. Rain, snow, or high winds can complicate operations. It's vital to halt work in unsafe weather. Safety plans should be reviewed regularly. Reflecting on past incidents can provide valuable lessons. Regular drills can prepare teams for unexpected challenges.

Essential Equipment for Efficient Crane Picking in 2026

In 2026, efficient crane picking relies heavily on essential equipment. First, a reliable load chart is crucial. It helps operators determine safe load limits. Miscalculations can lead to accidents, making this tool indispensable. A sturdy remote control system can also enhance safety. It allows operators to manage the crane from a safe distance, reducing risks.

When selecting attachments, consider using a spreader beam. This tool distributes weight evenly, reducing stress on the crane. High visibility during operations is vital. Use lights and reflective gear on your equipment and personnel. Without these, situations may quickly become dangerous.

Tip: Regularly inspect all equipment for wear and tear. Neglecting maintenance results in unexpected failures. Operators should stay agile and adapt to changing site conditions. This can be challenging, especially in busy environments. Adjustments are necessary but often overlooked. Recognizing areas for improvement makes crane operations safer and more effective.

Techniques to Optimize Crane Loading and Unloading Processes

In 2026, optimizing crane loading and unloading processes is crucial. Effective techniques can enhance safety and efficiency. Start by assessing the crane's capacity and the load's weight. Misjudging these can lead to dangerous situations. Use digital tools for real-time load monitoring. This helps prevent overloading and ensures safer operations.

Regular training for crane operators is essential. Skilled operators can navigate complex environments and avoid mishaps. Employing ground spotters can also improve safety and communication. They provide visual guidance and signal during lifting. Conducting routine inspections and maintenance is vital. Neglecting this may lead to equipment failure and accidents.

Consider automating some processes, but don’t rush. Automation can improve efficiency, yet it requires careful planning. Not all loads are suitable for automation. Evaluating each situation helps prevent mistakes. In 2026, reflecting on these methods will drive improvement and ensure crane operations remain safe and effective.

Crane Loading and Unloading Efficiency in 2026

Future Trends in Crane Technology and Operations for Enhanced Efficiency

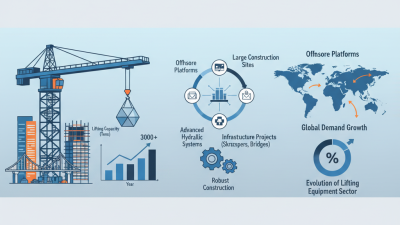

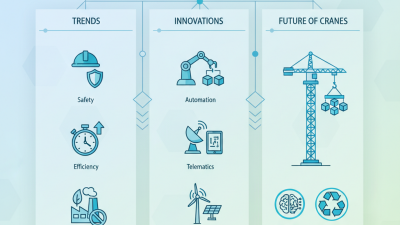

The landscape of crane technology is evolving rapidly. In 2026, the focus will be on smart cranes equipped with advanced sensors. These sensors can monitor load weights in real time. They help prevent overloading. This technology can greatly reduce accidents on job sites.

Automation is also a significant trend. Remote-operated cranes will be common. Operators can control cranes from safe distances. This will enhance safety and efficiency, but it requires strong connectivity. Not every site can guarantee stable internet. Furthermore, training new operators for these technologies is crucial. There's a gap to fill here.

Cost is another concern. High-tech cranes may initially appear expensive. However, their efficiency will lower operational costs over time. Companies must balance upfront investments with long-term savings. Embracing these trends will be essential. Without adaptation, companies may struggle to keep up in a competitive market.

How to Use a Crane Picking Up Crane Effectively in 2026? - Future Trends in Crane Technology and Operations for Enhanced Efficiency

| Year | Crane Type | Lifting Capacity (tons) | Technology Features | Operational Efficiency (%) |

|---|---|---|---|---|

| 2026 | Electric Tower Crane | 120 | Autonomous operation, Remote monitoring | 95 |

| 2026 | Rough Terrain Crane | 80 | Smart sensors, Advanced stability control | 92 |

| 2026 | Crawler Crane | 150 | Hybrid power system, IoT connectivity | 90 |

| 2026 | Mobile Crane | 100 | Real-time load monitoring, GPS tracking | 93 |

Related Posts

-

What is the Largest Crane in the World and Its Incredible Capabilities

-

Exploring the Future: 2025's Largest Crane Innovations and Trends

-

Top 10 Company Cranes to Watch in 2025: Trends and Innovations

-

How to Safely Use a Crane for Lifting and Rigging in Construction

-

Top 10 Tips for Effective Crane Lifting Techniques and Safety Best Practices

-

What is a Truck Boom Crane and How Does it Work in Construction