10 Essential Tips for Operating a Telescopic Crane Safely and Efficiently

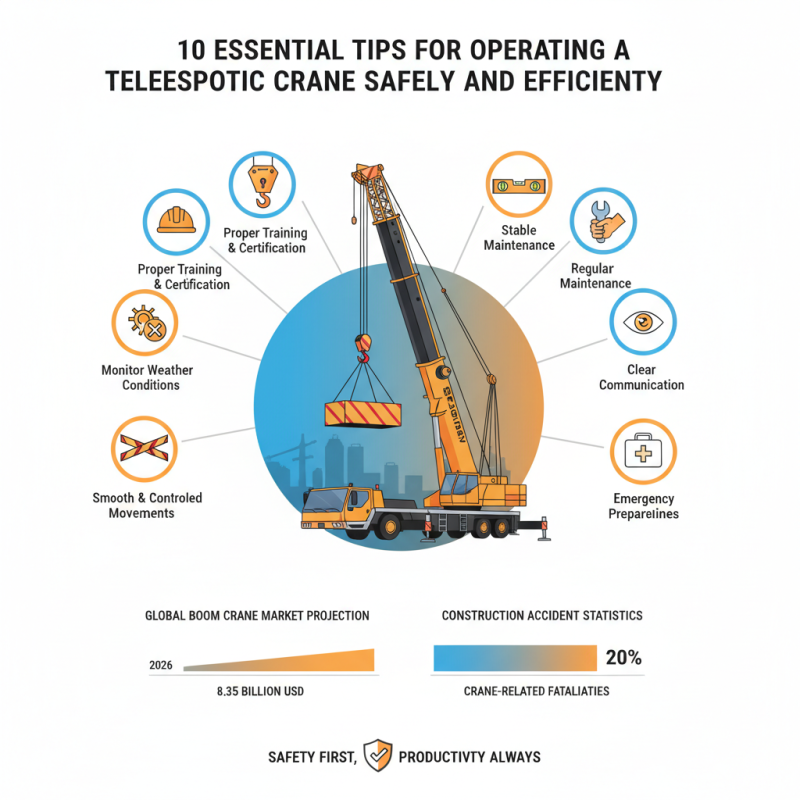

In the realm of heavy lifting, the telescopic crane stands out as a versatile and essential piece of machinery. According to industry reports, the global boom crane market is projected to reach approximately $8.35 billion by 2026, with telescopic cranes taking a significant share of this growth due to their ability to extend and retract their booms. This adaptability not only maximizes lifting capabilities but also enhances operational efficiency on construction sites, where space and maneuverability are often limited.

However, operating a telescopic crane presents unique challenges that demand a high level of skill and safety awareness. The Occupational Safety and Health Administration (OSHA) emphasizes that improper crane operation is a leading cause of workplace accidents in the construction industry. With statistics revealing that roughly 20% of fatalities involve cranes, it becomes imperative for operators to prioritize safety and adhere to best practices. Implementing efficient operational techniques alongside stringent safety measures can significantly reduce risks and contribute to a more productive work environment. This article outlines ten essential tips for operating a telescopic crane safely and efficiently, ensuring that both operators and crew members remain protected while maximizing performance on the job site.

Importance of Safety Training for Telescopic Crane Operators

Safety training for telescopic crane operators is paramount in ensuring that construction sites are secure and operations run smoothly. Understanding the mechanics of the crane, load limits, and environmental factors can significantly reduce the risk of accidents. Training programs should encompass not only the operational aspects of the machinery but also situational awareness, hazard recognition, and emergency response procedures. Knowledgeable operators are more capable of making informed decisions and identifying potential risks before they escalate into serious incidents.

Moreover, ongoing education and certification are crucial in an industry that continually evolves with new technologies and regulations. Regular training sessions help operators stay up-to-date with the latest safety protocols and operational techniques, promoting a culture of safety on site. This commitment to continuous improvement not only safeguards the operators but also protects the workers around them, enhancing overall operational efficiency by minimizing downtime caused by accidents.

Ultimately, investing in comprehensive safety training for telescopic crane operators is an investment in the well-being of everyone involved in the construction process.

Understanding the Key Components and Functions of Telescopic Cranes

Telescopic cranes are vital equipment in construction and industrial settings, known for their ability to lift and extend considerable loads. Understanding the key components of these cranes is crucial for ensuring their safe and efficient operation. The primary elements include the boom, which can extend and retract to adjust the reach; the base, which provides stability; and the lifting mechanism, typically a combination of hydraulic systems and cables. Each of these parts plays a significant role in determining the crane's capability and overall performance.

Furthermore, the function of a telescopic crane relies heavily on its hydraulic system. The hydraulic cylinders enable the boom to extend and retract smoothly, allowing for precise control during operations. Operators must be familiar with the crane's load charts and operational limits, as exceeding these can lead to safety hazards. Proper maintenance of the hydraulic components is also essential to prevent failures that could jeopardize both the equipment and personnel on-site. By having a comprehensive understanding of these core components and their functions, operators can enhance their ability to work safely and efficiently with telescopic cranes.

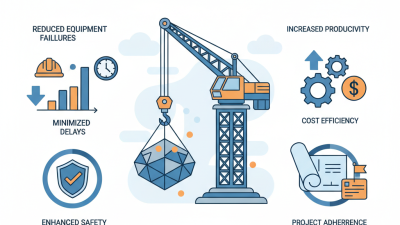

Safety and Efficiency Metrics for Telescopic Crane Operations

Pre-Operation Inspection: Steps to Ensure Equipment Readiness

Before operating a telescopic crane, it is imperative to conduct a thorough pre-operation inspection to ensure the equipment is in optimal working condition. This process should start with a detailed visual examination of the crane's structure, looking for any signs of wear, damage, or corrosion. Inspect the boom, outriggers, and cables for any defects that could compromise the crane's stability and performance. Pay special attention to the hydraulic system for leaks and ensure that all fluid levels are within safe operational limits.

In addition to physical inspections, it is crucial to test the operation of all controls and emergency systems. Make sure that the load limit switch, emergency stop buttons, and safety alarms are functioning properly. Regularly checking these features helps mitigate risks during operation. One essential tip to remember is to verify that all operators are familiar with the crane's functions and safety features before beginning work, fostering a culture of safety on site.

Moreover, ensuring that the crane is set up on stable ground and that the area is clear of obstacles can prevent potential accidents. Always check the weather conditions as well; high winds can significantly affect crane operations. Ultimately, a comprehensive pre-operation inspection is vital for safe and efficient use, empowering operators to work confidently while minimizing hazards.

Best Practices for Load Management and Stability

When operating a telescopic crane, effective load management and stability are paramount to ensure safety and operational efficiency. According to the American Society of Civil Engineers, improperly managed loads are a leading cause of crane accidents, contributing to approximately 40% of all incidents in the construction sector. One critical practice for load management is to always adhere to the crane’s rated load capacity, which should be clearly marked on the crane. Operators must also consider load dynamics, including the effects of wind and the load's center of gravity, to prevent tipping or instability.

Another best practice involves implementing a thorough pre-operation checklist that emphasizes load identification and rigging requirements. Data from the Occupational Safety and Health Administration (OSHA) indicate that nearly 50% of crane-related fatalities were linked to inadequate rigging practices. Operators should ensure that all rigging equipment is suitable for the load type and weight, following manufacturer specifications and industry guidelines. Additionally, communication among team members is essential; using standardized signals to coordinate lifting operations can significantly reduce the risk of mishaps. Regular training and refreshers on load management techniques can further enhance safety and operational integrity, ensuring that all personnel are well-versed in best practices.

Emergency Procedures: Preparing for Unexpected Situations

When operating a telescopic crane, preparation for emergencies is crucial to ensure the safety of all personnel involved and the integrity of the equipment. Before commencing operations, crews should conduct thorough risk assessments to identify potential hazards that could arise in emergency situations. This includes understanding the site layout, recognizing potential obstacles, and ensuring all team members are trained in emergency response protocols. Regular drills should be scheduled to familiarize crew members with evacuation procedures and the proper use of safety equipment, ensuring swift action when unexpected situations emerge.

Moreover, having a comprehensive emergency plan in place is vital. This plan should detail specific procedures for various scenarios, such as equipment failure, adverse weather conditions, or personnel accidents. In addition to clearly outlining steps to halt operations and secure the area, the emergency plan must also include communication procedures to alert on-site personnel and emergency services efficiently. Ensuring that emergency contact numbers are easily accessible and that all operators know the nearest access points for first responders can make a significant difference during critical moments, ultimately promoting a safer working environment where every team member knows their role in an emergency.

Related Posts

-

The Best All Terrain Crane Models for Your Heavy Lifting Needs in 2023

-

What is a Boom Crane? Understanding Its Types, Uses, and Benefits

-

Exploring the Future: 2025's Largest Crane Innovations and Trends

-

Top 10 Company Cranes to Watch in 2025: Trends and Innovations

-

Why You Should Choose a Robust Crane for Your Heavy Lifting Needs

-

7 Best Lifting Cranes for Efficient Heavy Lifting in 2023