Why You Should Choose a Robust Crane for Your Heavy Lifting Needs

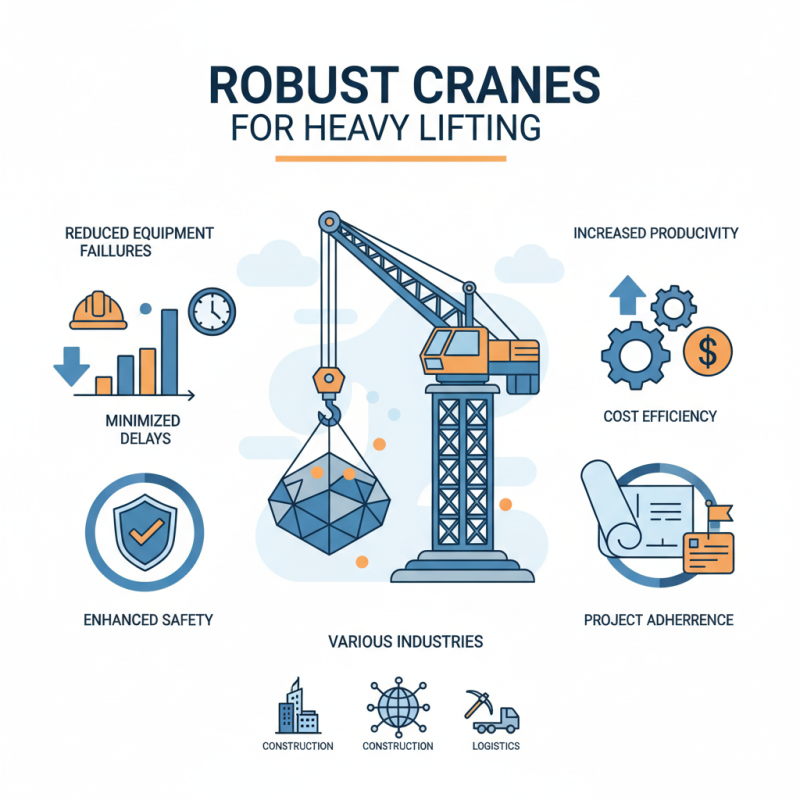

In the dynamic and demanding landscape of heavy lifting, the choice of equipment is critical to operational success. Robust cranes have emerged as an essential tool, delivering heightened performance and reliability to various industries, including construction, mining, and logistics. According to a report by the International Crane and Rigging Association (ICRA), approximately 60% of construction delays can be attributed to equipment failures, underscoring the need for durable and dependable machinery. A robust crane significantly minimizes the risks associated with these failures, ensuring that projects adhere to timelines and budgets.

Industry expert John Matthews, a leading authority on heavy machinery, emphasizes this need: "Investing in a robust crane is not just a choice; it's a commitment to safety and efficiency in heavy lifting operations." His insights reflect a growing consensus among professionals that prioritizing quality and strength in equipment can enhance not only productivity but also worker safety. As organizations strive to improve their operational effectiveness, the adoption of robust cranes is poised to play a pivotal role in achieving these goals, effectively addressing the evolving challenges of heavy lifting in today's competitive environment.

Factors to Consider When Choosing a Crane for Heavy Lifting

When choosing a crane for heavy lifting, several critical factors should be taken into account to ensure optimal performance and safety. Firstly, assessing the load capacity of the crane is essential. Cranes come with various weight ratings, and it's crucial to select one that can handle the maximum load you intend to lift. According to industry reports, cranes engineered for higher load capacities generally demonstrate durability and stability in operations, reducing the risk of accidents and equipment failure.

Another factor to consider is the working environment where the crane will be used. Indoor versus outdoor operations present different challenges, such as space constraints and ground stability. For instance, rough terrain may require a crane with enhanced mobility and stabilization features. Additionally, the height and reach requirements play a significant role; cranes must be able to maneuver effectively while maintaining safety.

Tips: Always conduct a thorough inspection of the crane's components, including its boom, hoists, and safety mechanisms. Training and certification for operators are likewise vital, as improper use can lead to significant risks. Furthermore, consider opting for cranes equipped with advanced technology for load monitoring to enhance operational safety and efficiency.

Investing time in evaluating these factors will not only bolster operational effectiveness but also enhance workplace safety. Being informed of the specifications and capabilities of potential cranes will lead to better long-term investments.

Types of Cranes Suitable for Heavy Lifting Applications

When it comes to heavy lifting applications, selecting the right type of crane is crucial for efficiency and safety. Several types of cranes are specifically designed to handle substantial weights, including tower cranes, crawler cranes, and overhead cranes. According to industry reports, tower cranes are often used in construction, capable of lifting loads of up to 20 tons at a time, making them perfect for high-rise buildings. Crawler cranes, known for their mobility and stability, can lift even heavier loads, sometimes exceeding 100 tons while traversing various terrains.

When considering a crane for heavy lifting, it's essential to evaluate the specific requirements of your project. Understanding the maximum weight capacity, the height and reach needed, and the terrain of the job site can significantly impact your choice.

**Tip:** Always consult with industry professionals to ensure that the selected crane meets the operational demands and safety regulations.

Additionally, overhead cranes are widely utilized in manufacturing and warehouses for their ability to lift items along a fixed path, thus optimizing space and enhancing productivity. Their capacity can range widely, with some models lifting thousands of kilograms featuring advanced controls for precision handling.

**Tip:** Regular maintenance and inspections are vital to ensuring the longevity and reliability of your crane, which plays an essential role in the overall safety of your work environment.

Why You Should Choose a Robust Crane for Your Heavy Lifting Needs

| Type of Crane | Suitable Applications | Max Load Capacity | Common Features |

|---|---|---|---|

| Crawler Crane | Offshore platforms, construction sites | Up to 3,000 tons | Mobile, tracks for rough terrain |

| Tower Crane | High-rise buildings, large construction projects | Up to 20 tons | Height adjustable, 360-degree rotation |

| Rough Terrain Crane | Construction sites, oil and gas fields | Up to 50 tons | 4-wheel drive, off-road capabilities |

| Mobile Crane | Industrial sites, road construction | Up to 1,200 tons | Easily transportable, versatile usage |

| Loader Crane | Logistics, delivery | Up to 30 tons | Compact design, mounted on trucks |

Advantages of Using a Robust Crane for Heavy Loads

When it comes to heavy lifting, the choice of a crane can significantly impact the efficiency and safety of operations. A robust crane is specifically designed to handle the challenges associated with heavy loads, offering several advantages that make them an indispensable asset in various industries. According to the American Society of Civil Engineers, construction sites that utilize high-capacity cranes can reduce the risk of accidents by up to 30%, highlighting the importance of choosing the right equipment for the job.

One of the primary benefits of using a robust crane is its capability to lift substantial weights with precision. Robust cranes are engineered with advanced materials and technologies that enhance their load-bearing capacity. For instance, a report from the Crane Industry Council of America indicates that modern heavy lifting cranes can handle loads exceeding 1,000 tons, making them ideal for projects involving heavy machinery, steel structures, and infrastructure components. This capability not only increases productivity but also minimizes the number of lifting operations required, thereby reducing downtime.

Additionally, robust cranes are equipped with enhanced stability features, which are critical when dealing with heavy loads. The inclusion of outriggers and counterweights allows these cranes to maintain balance, ensuring safe operations even on uneven terrain. Industry statistics show that cranes with stability enhancements report fewer operational incidents, reinforcing the necessity of selecting a crane designed for heavy lifting. This safety assurance contributes to a more secure work environment, ultimately promoting efficiency and reducing project delays.

Safety Features to Look for in Heavy Lifting Cranes

When selecting a heavy lifting crane, safety features are paramount. One of the most crucial aspects to consider is the load limit indicator. This feature ensures that the crane does not exceed its safe lifting capacity, thereby reducing the risk of accidents and structural failures. An accurate overload protection system can prevent catastrophic incidents that may arise from lifting more than the equipment can handle.

Another important safety feature is the stability control system. Cranes should be equipped with stabilizers or outriggers that help maintain balance during operations. This feature is essential, especially when lifting heavy loads at height or on uneven surfaces. A crane that provides real-time feedback regarding its stability can significantly enhance the operator's ability to make informed decisions while handling heavy materials.

Additional safety mechanisms to look for include emergency stop buttons, visual and audible alarms, and comprehensive operator training programs. These elements not only safeguard the operators but also promote a culture of safety within the workplace. In essence, investing in cranes that prioritize these safety features can lead to more efficient operations and a secure working environment.

Maintenance Tips to Ensure Longevity of Your Crane

When it comes to heavy lifting, choosing a robust crane is only part of the solution. Maintenance is essential to ensure the longevity and reliable performance of your crane. According to the Occupational Safety and Health Administration (OSHA), properly maintained cranes reduce the occurrence of accidents and downtime by up to 40%. This emphasizes that ongoing care is not just beneficial—it's vital for safety and efficiency.

To extend the lifespan of your crane, regular inspections and preventative maintenance are key. Routine checks should include assessing the rigging, hydraulic systems, and electrical components. Data from the Crane Institute of America indicates that cranes with a strict maintenance schedule can last 20-30% longer than those without. Additionally, keeping an accurate maintenance log can help identify patterns of wear and potential issues before they lead to costly repairs.

Tip: Implement a daily pre-operational check to ensure that all crane components are functioning correctly. This includes verifying that safety devices are operational and that there are no visible damages. Regular operator training is also crucial, as it ensures that all users are aware of the best practices for operating cranes safely and effectively, ultimately enhancing performance and safety standards.

Related Posts

-

Top 10 Company Cranes to Watch in 2025: Trends and Innovations

-

7 Best Lifting Cranes for Efficient Heavy Lifting in 2023

-

Exploring the Future: 2025's Largest Crane Innovations and Trends

-

2025 How to Choose the Best All Terrain Crane for Your Project

-

The Best All Terrain Crane Models for Your Heavy Lifting Needs in 2023

-

What is a Boom Crane? Understanding Its Types, Uses, and Benefits