How to Safely Operate a Wind Turbine Crane?

Operating a wind turbine crane safely is essential for both workers and equipment. Mike Turner, a renowned expert in wind energy, emphasizes, “Safety begins with proper training and awareness.” His insights are crucial for ensuring that crane operators are aware of their responsibilities.

Wind turbine cranes face unique challenges. They must operate in high altitudes and often adverse weather conditions. Each lift requires precise calculations and careful planning. Operators cannot take shortcuts; overlooking small details can lead to accidents. A seasoned operator shared that even a sudden wind gust can shift the load unexpectedly, creating hazardous situations.

Training programs must cover all aspects of crane operation. Operators should be familiar with the machinery and its limitations. Regular inspections and maintenance are vital to ensure safety. Reflecting on past incidents can also provide essential lessons. Learning from mistakes helps cultivate a culture of safety in the wind turbine industry.

Understanding the Importance of Safety in Wind Turbine Crane Operations

Operating a wind turbine crane comes with inherent risks. Safety must be the priority in each operation. Ensuring proper training for all personnel is crucial. This knowledge helps in managing unexpected situations effectively. The equipment must be inspected regularly. Even minor issues can escalate into serious problems if overlooked.

Communication on-site is vital. Clear signals prevent accidents. Everyone needs to understand their roles. Sometimes, misunderstandings happen. These can lead to dangerous scenarios. Maintaining a culture of safety awareness is essential. It's important to conduct regular safety drills. They prepare the team for real emergencies.

Weather conditions can change rapidly. Operators should always assess the environment before starting work. Adverse weather can complicate operations significantly. Equipment limitations must be respected. Familiarizing oneself with the crane’s specifications helps in making safer choices. In the end, careful planning and awareness of potential risks are key. Each operation is a chance to reflect on what can improve. Prioritizing safety ensures that all crew members return home safely.

How to Safely Operate a Wind Turbine Crane? - Understanding the Importance of Safety in Wind Turbine Crane Operations

| Safety Aspect | Description | Importance |

|---|---|---|

| Pre-Operation Inspection | Inspecting equipment and crane conditions before operation to identify any issues. | Ensures safe operation and helps prevent accidents caused by faulty equipment. |

| Operator Training | Providing comprehensive training for crane operators on safety protocols and emergency procedures. | Reduces risk of operator error, leading to higher safety standards during operations. |

| Weather Assessment | Evaluating weather conditions before operating a crane, as strong winds can pose challenges. | Critical for ensuring the stability and control of the crane during lifting operations. |

| Use of Personal Protective Equipment (PPE) | Mandating the use of hard hats, gloves, and harnesses while working near cranes. | Helps protect workers from injuries in case of accidents or equipment failures. |

| Regular Maintenance | Conducting scheduled maintenance checks and repairs of crane equipment. | Maintains operational efficiency and prevents breakdowns that could lead to unsafe situations. |

Key Components of Wind Turbine Cranes and Their Functions

Wind turbine cranes play a crucial role in the renewable energy sector. These cranes are designed to handle the heavy loads associated with wind turbine installation and maintenance. Key components include the boom, which provides lifting capability, and the hoist, essential for raising and lowering components. According to industry studies, approximately 60% of crane-related incidents occur during the hoisting process. This highlights the need for proper training and equipment understanding.

The counterweight system is another vital aspect. It ensures stability while lifting components that can weigh several tons. Inadequate counterweight can lead to tipping or load swings. Reports suggest that improper crane setup contributes to 40% of accidents, emphasizing the importance of pre-operation checks. Additionally, operator training programs should include real scenarios to improve understanding of equipment limits.

Safety features like limit switches and load sensors are critical. They prevent overloading and ensure controlled operation. However, many operators may overlook these features in routine checks. Some operators admit to complacency, especially in familiar settings. Regular assessments and refresher courses can mitigate this risk, ensuring all team members understand crane capabilities and limitations. Keeping a safety-first mindset is essential in this field.

Pre-Operation Safety Checks and Protocols for Wind Turbine Cranes

Pre-operation safety checks for wind turbine cranes are crucial. Operators must inspect all components before use. This includes checking the hoisting mechanism, cables, and control systems. Small issues can lead to significant problems later on.

Next, ensure that all safety devices are in working order. This includes limit switches and emergency stop buttons. Operators should go through the checklist methodically. Missing even one step can be detrimental. Procedures must also include reviewing weather conditions. High winds can make operation dangerous.

Communication among the crew is vital. Everyone must understand their roles. Misunderstandings can cause accidents. It's essential to hold briefings and discuss potential risks before starting work. Reflecting on past experiences can help improve safety protocols. Mistakes should guide future actions and decisions. Safety should always be the top priority.

Best Practices for Operating a Wind Turbine Crane Under Varying Conditions

Operating a wind turbine crane requires attention to safety and adaptability. Different environments bring unique challenges. Wind conditions can change rapidly. Always check the weather forecast before starting. High winds can make lifting operations unsafe.

**Tip:** Use a wind gauge to monitor conditions. This tool can provide real-time data on wind speed. Adjust your plan accordingly. If wind exceeds safe limits, postpone the lift.

Visibility is another crucial factor. Poor visibility can lead to accidents. Ensure all team members are equipped with communication devices. This keeps everyone informed and responsive.

**Tip:** Conduct a pre-operation briefing. Discuss visibility challenges and agree on signals. Clarity in communication can help prevent misunderstandings.

Finally, be aware of the ground condition. Heavy rain or snow can create slippery surfaces. This increases the risk of accidents. Regularly inspect the crane’s surroundings. Identify any potential hazards early.

**Tip:** Mark hazardous areas clearly. Use cones or barriers to alert workers. It’s a small step that could save lives. Always prioritize safety over urgency in every operation.

Wind Turbine Crane Operation Safety Metrics

Emergency Procedures and Contingency Plans for Crane Operations

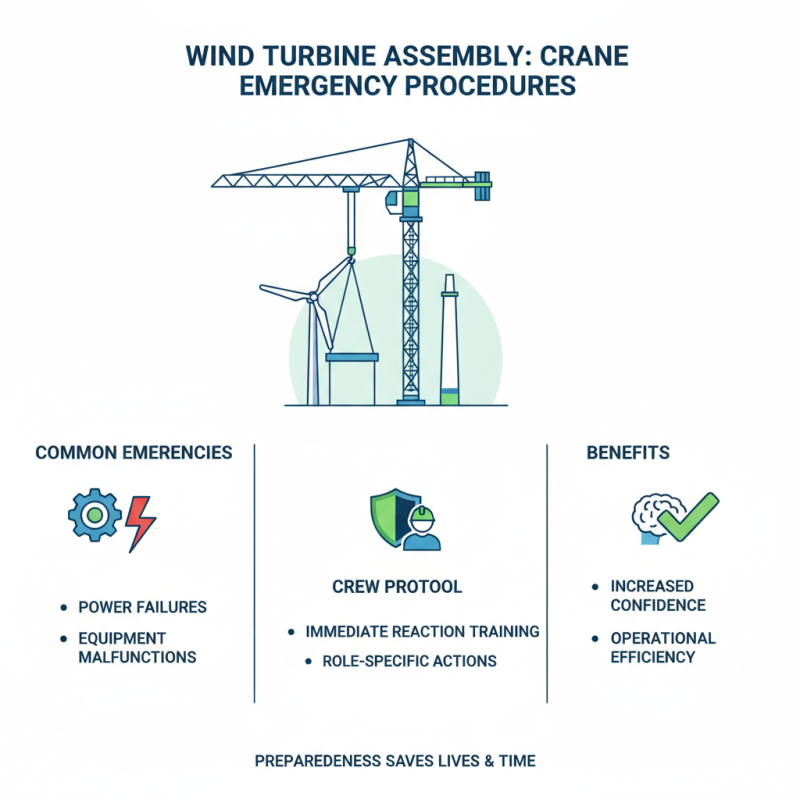

When operating a crane for wind turbine assembly, emergency procedures are crucial. Workers must know how to react during unexpected situations. Common emergencies include power failures or equipment malfunctions. Each team member should receive proper training on these scenarios. Familiarity breeds confidence and efficiency in emergencies.

Contingency plans must be well-documented and easily accessible. They should outline immediate steps when things go wrong. For instance, if a crane begins to sway, an operator must know to stop work quickly. Regular drills can help staff prepare. It's vital to review these plans often. Even experienced crews can overlook important details.

Despite thorough preparation, challenges may arise. Weather can change suddenly, affecting crane safety. Operators often underestimate wind speeds. There could always be minor oversights in the checklist. Reflecting on previous operations can lead to enhanced safety measures. Each incident becomes a learning opportunity, ensuring a safer future.

Related Posts

-

2025 Top Precision Crane Trends and Innovations You Need to Know

-

Essential Tips for Choosing the Best Truck Mounted Crane for Your Needs

-

2025 How to Choose the Best All Terrain Crane for Your Project

-

What is a Truck Boom Crane and How Does it Work in Construction

-

How to Safely Use a Crane for Lifting and Rigging in Construction

-

What is a Lattice Boom Crane and How Does It Work in Construction