How to Safely Operate a Wind Turbine Crane for Effective Installation

In the rapidly evolving renewable energy sector, the safe and effective operation of wind turbine cranes has become a critical focus for engineers and technicians alike. John Anderson, an industry expert with over two decades of experience in renewable energy installations, emphasizes the importance of prioritizing safety in this high-stakes environment. He states, "The integrity of a wind turbine installation depends not only on the equipment but also on the expertise of those operating it."

The complexity of working with a wind turbine crane is underscored by the various environmental factors and technical challenges that come into play during installation. Cranes must be operated with meticulous precision to ensure that large turbine components are lifted and positioned without risk of damage or accidents. As Anderson remarks, "Proper training and adherence to safety protocols can significantly reduce the likelihood of operational mishaps."

In this article, we will explore the essential guidelines and best practices for safely operating wind turbine cranes. By understanding the operational requirements, safety measures, and techniques for effective teamwork, industry professionals can enhance both installation efficiency and workplace safety. As the demand for clean energy continues to rise, mastering the operation of wind turbine cranes will play a pivotal role in the success of future wind energy projects.

Understanding the Mechanics of Wind Turbine Cranes

Understanding the mechanics of wind turbine cranes is crucial for ensuring the effective installation of wind energy systems. These specialized cranes are designed to handle the unique demands of lifting and positioning the towering components of wind turbines, which can weigh several tons. According to a report from the Global Wind Energy Council, the average weight of a wind turbine's nacelle alone can exceed 100 tons, necessitating the use of robust cranes capable of reaching significant heights and maneuvering in often challenging environments.

Operational safety is a primary concern when working with wind turbine cranes. A lift plan that includes detailed assessments of load capacities, crane stability, and weather conditions is essential. The American Society of Civil Engineers notes that wind speeds exceeding 20 mph can significantly impact the operational limits of cranes, making precise calculations and real-time monitoring vital.

Additionally, training for crane operators should emphasize understanding the mechanics of load dynamics and the importance of adhering to safety protocols to prevent accidents during installation operations. With wind energy projects becoming increasingly prominent, the effective use of crane technology is integral to the sustainable development of renewable energy infrastructure.

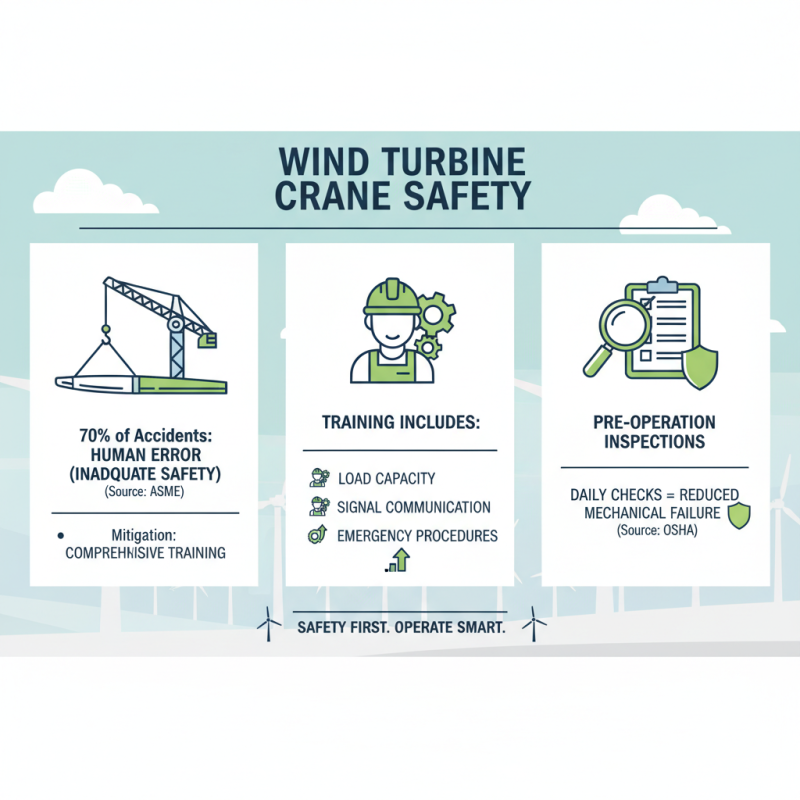

Safety Protocols for Operating Wind Turbine Cranes

Operating a wind turbine crane requires strict adherence to safety protocols to ensure both the effectiveness and safety of the installation process. According to a report from the American Society of Mechanical Engineers (ASME), approximately 70% of accidents in crane operations are attributed to human error and inadequate safety measures. To mitigate these risks, operators must undergo comprehensive training that includes the understanding of load capacities, signal communication, and emergency procedures. The importance of pre-operation inspections cannot be overstated; a study by the Occupational Safety and Health Administration (OSHA) notes that daily inspections can significantly reduce the likelihood of mechanical failure during operations.

Moreover, implementing a robust safety management system is crucial for wind turbine crane operations. The Global Wind Energy Council (GWEC) emphasizes the need for a safety-first culture, where every team member is encouraged to participate in safety discussions and report hazards without fear of reprisal. Adopting technologies such as load monitoring systems and geographic information systems (GIS) can enhance situational awareness, ultimately leading to safer operations. Furthermore, a well-structured communication plan ensures that all team members are on the same page regarding operational statuses and safety alerts, which can prevent accidents and improve response times in case of emergencies.

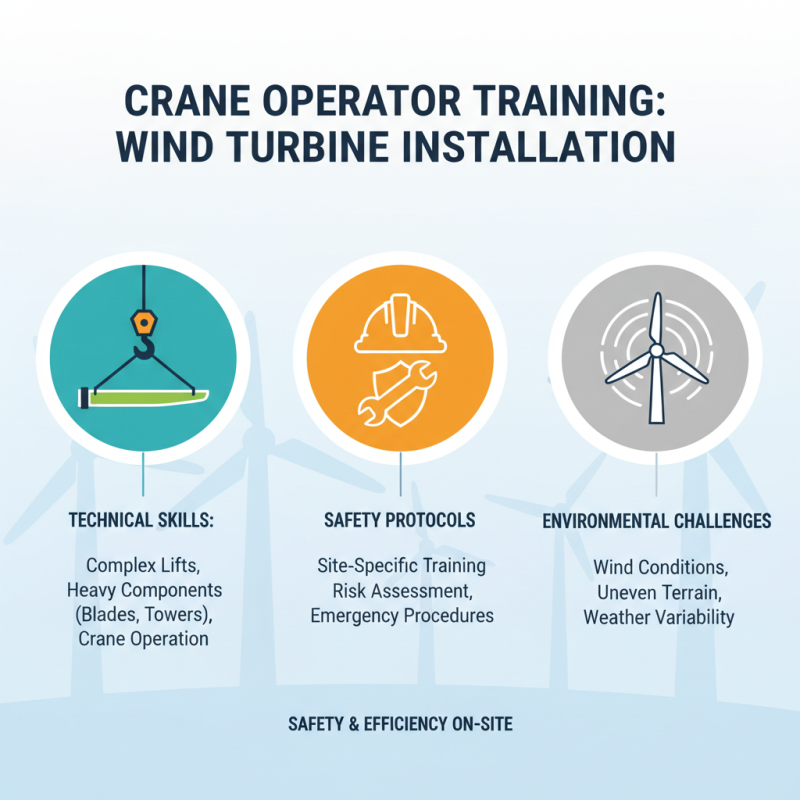

Essential Training for Crane Operators in Wind Turbine Installation

Essential training for crane operators in the installation of wind turbines is critical for ensuring both safety and efficiency on site. Wind turbine installation involves complex lifting operations that are performed in environments that can vary significantly, including windy conditions and uneven terrain. Operators must be well-versed in the specific requirements of lifting large and heavy components, such as turbine blades and towers, while also managing the unique challenges posed by the wind energy sector. A robust training program should encompass not only the technical skills required to operate cranes but also a comprehensive understanding of site safety protocols and risk assessment.

Operators should receive training that emphasizes hands-on experience with crane controls and mechanisms, load calculation, and the understanding of dynamic loads. It is essential for trainees to understand how external factors such as weather conditions, site layout, and nearby structures can impact lifting operations. Additionally, training should also include the importance of communication and teamwork, as effective collaboration with ground crews is vital for a successful installation process. Regular refreshers and ongoing education in advancements in crane technology and safety standards will help ensure that crane operators remain proficient and prepared to tackle the unique challenges presented within the wind turbine installation industry.

Planning and Preparing for Crane Setup at Wind Turbine Sites

Planning and preparing for crane setup at wind turbine sites involves several crucial steps to ensure a smooth and safe installation process. Before the crane arrives, project managers must carry out a thorough site assessment. This includes evaluating the terrain, identifying potential hazards such as power lines or nearby structures, and ensuring that the ground can support the weight of the crane and turbine components. A comprehensive environmental review can help in determining the best crane operating area while adhering to local regulations.

Additionally, meticulous logistical planning is essential. This involves coordinating delivery schedules for the crane and turbine parts, as well as planning for access routes that accommodate large vehicles. Clear communication among all team members, including crane operators, site supervisors, and logistics personnel, is vital to synchronize efforts and minimize delays. Lastly, conducting pre-lift meetings can establish safety protocols and ensure everyone understands their roles and responsibilities for the installation day. By prioritizing these preparatory steps, wind turbine installations can be executed efficiently and safely.

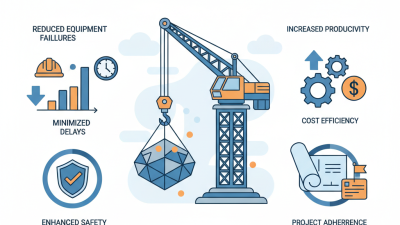

Wind Turbine Crane Setup - Safety and Efficiency

Best Practices for Conducting Safe Lift Operations with Cranes

When conducting lift operations with cranes for wind turbine installation, adherence to best practices is crucial to ensure safety and efficiency. First and foremost, operators should conduct a thorough site assessment before any lifting begins. This includes evaluating the ground conditions, identifying overhead hazards, and ensuring that the crane's working range is appropriate for the specific installation task. Establishing a clear communication plan among all team members is also vital; this ensures that everyone is aware of their roles and responsibilities during the lift, reducing the chances of miscommunication and accidents.

Proper equipment checks are essential for executing safe lift operations. Prior to any operation, cranes should undergo rigorous inspections to confirm that all components are functioning correctly. Operators should verify the load capacity and ensure that any lifting attachments are rated for the loads they will handle. Training and certification of personnel operating the crane must also be prioritized, as only skilled and knowledgeable operators can navigate the complexities of crane operation under varying wind conditions, which are prevalent in wind turbine installations. By implementing these best practices, teams can enhance safety and achieve effective outcomes during lift operations.

How to Safely Operate a Wind Turbine Crane for Effective Installation - Best Practices for Conducting Safe Lift Operations with Cranes

| Best Practice | Description | Importance | Frequency |

|---|---|---|---|

| Pre-Lift Planning | Conduct a thorough assessment of the site and equipment. | Ensures safety and identifies potential risks. | Every lift |

| Equipment Inspections | Regular checks on crane and rigging for defects. | Helps prevent accidents due to equipment failure. | Daily |

| Load Calculation | Calculate the weight and center of gravity of the load. | Prevents overloading and maintains crane stability. | Every lift |

| Communication Protocol | Establish clear communication between the crew members. | Ensures coordinated operations and mitigates risks. | Every lift |

| Weather Assessment | Monitor weather conditions that could affect lifting operations. | Prevents unsafe operations under adverse conditions. | Every operation |

Related Posts

-

Top 10 Company Cranes to Watch in 2025: Trends and Innovations

-

7 Best Lifting Cranes for Efficient Heavy Lifting in 2023

-

What is a Boom Crane? Understanding Its Types, Uses, and Benefits

-

Why You Should Choose a Robust Crane for Your Heavy Lifting Needs

-

2025 How to Choose the Best All Terrain Crane for Your Project

-

Exploring the Future: 2025's Largest Crane Innovations and Trends