Essential Tips for Choosing the Best Truck Mounted Crane for Your Needs

In the ever-evolving landscape of the construction and logistics industries, the demand for efficient and versatile lifting equipment has never been higher. Among the various options available, a truck mounted crane stands out due to its mobility and ability to perform a wide range of lifting tasks. According to a report by Grand View Research, the global crane market is expected to reach USD 52.4 billion by 2027, driven in part by the increasing need for lifting solutions that combine portability with heavy-load capabilities.

When selecting the best truck mounted crane for your specific needs, it is crucial to consider factors such as load capacity, reach, and overall versatility. Recent data from IBISWorld indicates a growing trend towards the adoption of advanced crane technologies, which enhance operational efficiency and safety. With the right crane, businesses can improve their productivity and reduce operational downtime, thereby impacting their bottom line positively.

This comprehensive guide aims to provide essential tips to help you navigate the various features and specifications of truck mounted cranes, ensuring you make an informed decision that meets your operational requirements and enhances your project outcomes.

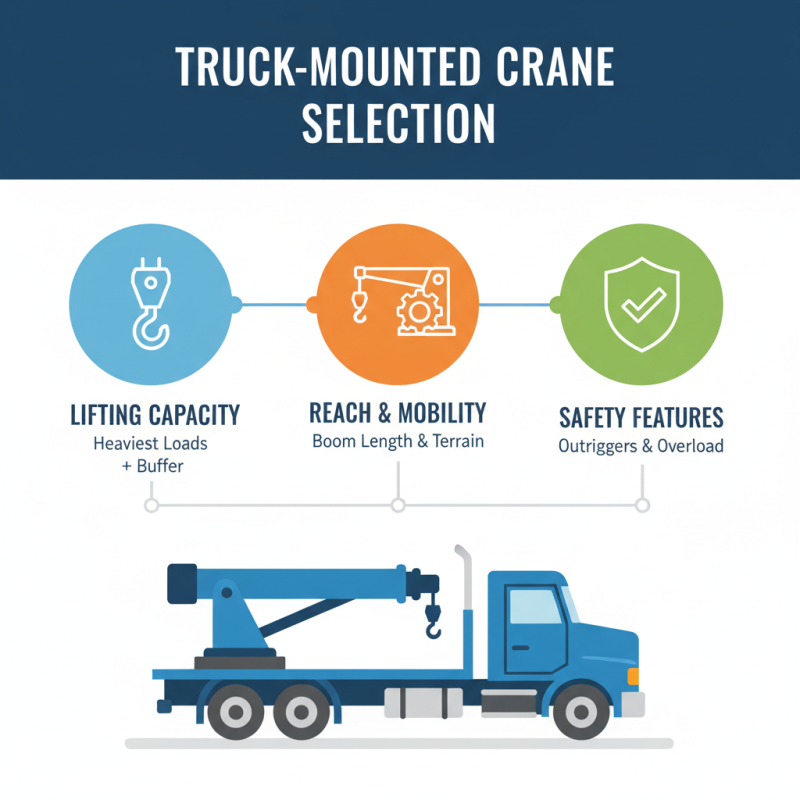

Factors to Consider When Selecting a Truck Mounted Crane for Your Projects

When selecting a truck mounted crane for your projects, it’s crucial to consider several key factors that can greatly impact both performance and safety. First, evaluate the lifting capacity required for your tasks. This capacity will depend on the heaviest loads your operations will typically involve. Make sure to choose a crane that not only meets this requirement but also provides a buffer to account for unexpected weight variations.

In addition to lifting capacity, assess the crane's reach and working height. Different jobs may require the crane to extend over obstacles or lift materials to significant heights. Ensure that the selected crane can adequately meet these demands. Furthermore, examine the stability and maneuverability of the crane; factors such as the base width and axle count can significantly influence how well it performs in various conditions. These considerations will help ensure that the crane you choose can effectively handle your specific project requirements while maintaining safety and efficiency on the job site.

Understanding Load Capacity Requirements for Truck Mounted Cranes

When selecting a truck mounted crane, understanding load capacity requirements is crucial to ensure optimal performance and safety. Load capacity, often measured in tons, refers to the maximum weight a crane can lift at a given radius. According to industry reports, the average capacity of truck mounted cranes ranges from 10 to 60 tons, depending on factors such as crane design, model, and specifications. It's essential to assess the nature of the tasks you intend to perform—whether lifting heavy machinery, constructing buildings, or handling materials on a job site—as this will help determine the appropriate load capacity needed.

In addition to the weight, the load's distribution and the reach required play critical roles in selecting the right crane. Research indicates that cranes operating at full capacity may not always provide the same reach as those lifting lighter loads. For instance, a truck mounted crane with a 20-ton capacity may only safely lift that weight at a shorter radius, typically under 25 feet, while a larger reach may require a significant reduction in load capacity. It's imperative to analyze job site conditions, including terrain and height restrictions, to ensure the selected crane meets not only the weight requirements but also operational versatility and safety standards in different environments.

Load Capacity Requirements for Truck Mounted Cranes

This chart illustrates the load capacity of various truck-mounted cranes based on their model classification. Understanding these capacities is essential for selecting the right crane for specific applications.

Evaluating the Reach and Height Specifications of Different Models

When selecting a truck-mounted crane, evaluating the reach and height specifications is crucial to ensure it meets your operational needs. According to recent industry reports, cranes with a higher reach typically range from 20 to 60 feet, depending on the model and design. It’s important to analyze the specific tasks you plan to undertake. For example, construction projects may require equipment that can reach significant heights to accommodate multi-story building frameworks, while utility work might need cranes with extended horizontal reach for tasks such as overhead line maintenance.

Moreover, the vertical and horizontal reach specifications should be directly aligned with the job site requirements. As outlined in a 2023 market analysis, cranes that provide a flexible boom and extendable arms allow operators to efficiently maneuver in tight spaces, making them ideal for urban environments where space is limited. Models that can articulate or telescope not only improve overall reach but also enhance safety by allowing operators to position loads without compromising stability. Thus, carefully assessing the reach and height capabilities of different truck-mounted cranes will enable you to select the right equipment for your specific applications, maximizing productivity and safety on the job.

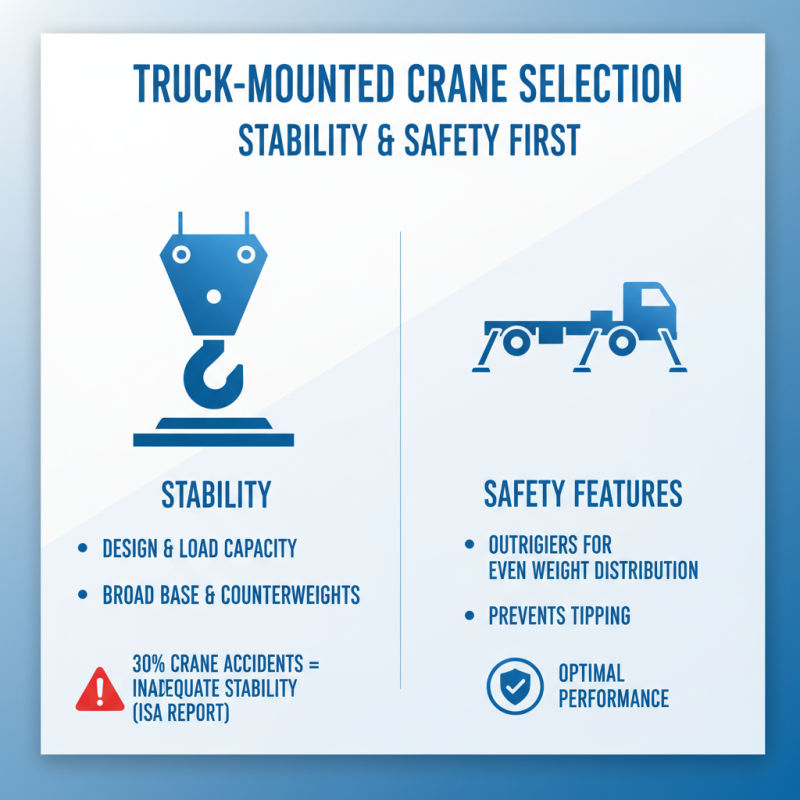

Assessing Crane Stability and Safety Features for Optimal Performance

When selecting a truck-mounted crane, assessing stability and safety features is paramount to ensure optimal performance. Stability is primarily influenced by the crane's design and load capacity. According to a report by the International Society of Automation (ISA), nearly 30% of crane accidents are attributed to inadequate stability. A well-designed crane should feature a broad base and sufficient counterweights to prevent tipping during operation. Furthermore, cranes equipped with outriggers can enhance stability significantly by distributing the weight more evenly across the truck chassis.

Safety features play a crucial role in protecting both the operator and general workforce. Key safety components include overload protection systems, which prevent lifting beyond the crane’s capacity, and stability indicators that provide real-time feedback on the crane's positioning. The American Society of Mechanical Engineers (ASME) emphasizes that cranes should be fitted with features like emergency stop buttons and anti-collision systems to further mitigate risks. Regular inspections and adherence to safety standards can prevent accidents, with the Occupational Safety and Health Administration (OSHA) reporting that compliance can reduce workplace incidents by up to 40%. Prioritizing these stability and safety features when choosing a truck-mounted crane will not only enhance operational efficiency but also safeguard personnel on site.

Comparing Maintenance Costs and Lifespan of Various Truck Mounted Cranes

When considering a truck-mounted crane, maintenance costs and lifespan are critical factors that can significantly affect your investment. According to a report by the National Crane Owners Association, regular maintenance can reduce unexpected failures, extending the lifespan of the crane to upwards of 15 years. The report indicates that cranes that undergo preventive maintenance can experience up to 25% lower operational costs compared to those that do not, highlighting the importance of choosing a model that allows easy access for inspections and repairs.

Different truck-mounted crane models come with varying maintenance requirements. A study conducted by the Construction Equipment Manufacturers Association shows that hydraulic cranes typically have a much lower failure rate, thus resulting in lower maintenance expenses. In fact, these cranes can potentially save operators thousands of dollars annually in service costs compared to mechanical models due to their advanced components that are designed for durability. Moreover, evaluating the ease of replacing parts can also influence long-term costs; cranes with readily available components often minimize downtime, ensuring continuous operation.

Understanding the balance between initial purchase price and long-term maintenance is essential for selecting the right crane. A comprehensive analysis that includes total cost of ownership, including projected maintenance costs over the lifespan of the equipment, allows businesses to make informed purchasing decisions tailored to their operational needs. Prioritizing these factors not only enhances productivity but also ensures that the crane serves effectively for its intended purpose over the long haul.

Essential Tips for Choosing the Best Truck Mounted Crane for Your Needs - Comparing Maintenance Costs and Lifespan of Various Truck Mounted Cranes

| Crane Model | Max Load Capacity (lbs) | Maintenance Cost (Annual) | Lifespan (Years) | Notes |

|---|---|---|---|---|

| Model A | 15,000 | $2,500 | 10 | Ideal for urban construction |

| Model B | 20,000 | $3,200 | 12 | Great for heavy lifting |

| Model C | 25,000 | $4,000 | 15 | Suitable for industrial sites |

| Model D | 30,000 | $5,500 | 20 | Best for construction sites |

| Model E | 18,000 | $2,900 | 11 | Versatile for various tasks |

Related Posts

-

What is a Truck Boom Crane and How Does it Work in Construction

-

What is the Largest Crane in the World and Its Incredible Capabilities

-

How to Safely Operate a Wind Turbine Crane for Effective Installation

-

Why You Should Choose a Robust Crane for Your Heavy Lifting Needs

-

How to Safely Use a Crane for Lifting and Rigging in Construction

-

2025 How to Choose the Best All Terrain Crane for Your Project