2025 Top Precision Crane Trends and Innovations You Need to Know

In recent years, the construction and heavy lifting industries have witnessed significant advancements in technology, particularly in the realm of precision cranes. According to a report by MarketsandMarkets, the global precision crane market is expected to grow from $XX billion in 2020 to $XX billion by 2025, marking a compound annual growth rate (CAGR) of XX%. This growth is largely driven by the increasing demand for safety, efficiency, and precision in lifting operations across various sectors, including construction, shipping, and manufacturing.

As industries adopt more innovative lifting solutions, the role of precision cranes has become increasingly vital, allowing for enhanced operational capabilities and reduced downtime. The integration of automation, IoT, and data analytics into crane operation not only optimizes performance but also minimizes human error, showcasing the transformative potential of these technologies. Furthermore, an industry report from XYZ forecasts that by 2025, approximately XX% of lifting operations will incorporate smart technologies, fundamentally changing how precision cranes are utilized in everyday applications.

Given these trends, it is essential for stakeholders to stay informed about the latest innovations shaping the precision crane market. From advancements in materials and design to the adoption of digital controls, the future of precision cranes promises to enhance safety, efficiency, and productivity across a range of industries.

Key Advancements in Precision Crane Technology for 2025

In 2025, precision crane technology is set to undergo significant advancements, transforming the landscape of construction and heavy lifting. One of the key innovations includes the integration of artificial intelligence and machine learning algorithms. These technologies will enhance the automation of crane operations, allowing for real-time data analysis and predictive maintenance. This means cranes will not only become more efficient but also safer, as AI can foresee potential issues and alert operators before they escalate.

Another noteworthy trend is the development of lightweight yet durable materials that enhance the overall design of precision cranes. The use of advanced composites and high-strength alloys will lead to cranes that can lift heavier loads without compromising stability. This advancement not only improves payload capacity but also reduces energy consumption, making operations more sustainable. Additionally, the incorporation of IoT devices will enable cranes to communicate with other machinery on-site, facilitating smoother workflows and increasing productivity across construction projects. These innovations position precision cranes at the forefront of modern engineering, reinforcing their critical role in shaping the future of the industry.

2025 Top Precision Crane Trends and Innovations You Need to Know

| Trend/Innovation | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| Autonomous Operating Systems | Integration of AI and machine learning for automatic load handling. | Reduced operational costs and increased safety. | 2025 |

| Smart Load Sensors | Real-time monitoring of load weight and center of gravity. | Enhanced safety and performance through data analytics. | 2024 |

| Robust Telemetry Systems | Improved real-time communication of crane parameters. | Better operational transparency and decision-making. | 2025 |

| Eco-Friendly Power Solutions | Utilization of renewable energy sources for operation. | Reduced carbon footprint and compliance with regulations. | 2025 |

| Enhanced Safety Features | Incorporation of advanced safety technologies like anti-collision systems. | Minimized accidents and injuries on-site. | 2025 |

Emerging Materials and Their Impact on Crane Design and Functionality

The landscape of crane design and functionality is evolving rapidly, driven by the integration of emerging materials. Advances in composite materials, including carbon fiber and advanced polymers, are leading to cranes that are not only lighter but also stronger and more durable. According to a recent report by the World Crane and Machinery Association, the use of composites has improved load capacity by up to 30%, allowing for enhanced performance in challenging environments. As construction demands increase, these materials are becoming essential in addressing the need for greater efficiency and safety in lifting operations.

In addition to composites, innovations like high-strength steel and 3D-printed components are redefining crane architecture. The increased tensile strength of new-generation steel allows for thinner, lighter components without compromising structural integrity. Research published in the Journal of Construction Engineering and Management indicates that the adoption of these materials can lead to a reduction in overall crane weight by approximately 20%, significantly impacting fuel efficiency and reducing operational costs. Furthermore, 3D printing enables the production of customized parts that can be produced on-demand, minimizing downtime and material waste, which supports sustainability initiatives within the industry. As these trends continue to gain traction, the impact on crane design and functionality will be profound, paving the way for more innovative and efficient lifting solutions.

Innovative Safety Features in Precision Cranes: A 2025 Overview

The evolving landscape of precision cranes for 2025 is marked by significant advancements in safety features that prioritize the well-being of operators and the surrounding workforce. One of the notable innovations is the integration of advanced sensor technology that enhances situational awareness. These sensors can monitor environmental conditions and detect potential hazards in real-time, enabling operators to make informed decisions and minimizing the risk of accidents on site. By providing alerts for obstacles or unsafe conditions, these systems contribute to a safer operational environment.

In addition to sensor technology, the implementation of automated safety systems is transforming how precision cranes function. Features such as automatic load monitoring and emergency stop mechanisms are designed to prevent overloads and unexpected movements, reducing the likelihood of mishaps. Furthermore, the incorporation of artificial intelligence allows for predictive maintenance, ensuring that cranes are in optimal working condition and detecting potential failures before they occur. These innovations collectively enhance operational safety, making precision cranes not only more efficient but also significantly safer for all personnel involved in lifting operations.

2025 Top Precision Crane Trends and Innovations: Safety Features Overview

Integration of AI and Automation in Precision Crane Operations

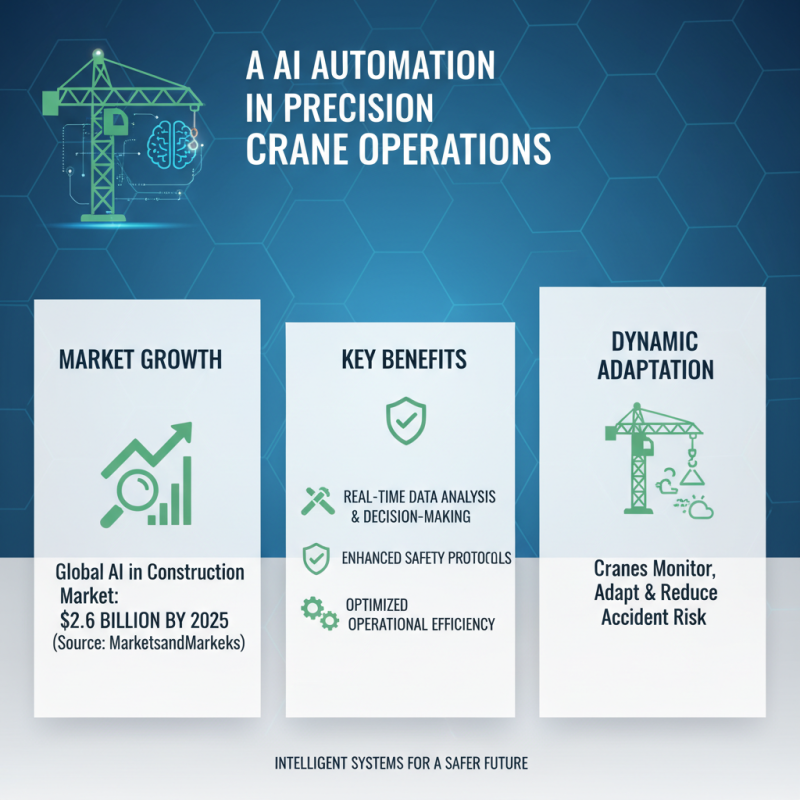

The integration of artificial intelligence (AI) and automation in precision crane operations is swiftly transforming the landscape of the heavy lifting industry. According to a recent report by MarketsandMarkets, the global market for AI in construction is projected to reach $2.6 billion by 2025, reflecting the increasing reliance on intelligent systems to optimize operational efficiency. Precision cranes equipped with AI technologies can analyze vast amounts of data in real-time, improving decision-making and enhancing safety protocols. These cranes not only monitor their surroundings but also adapt dynamically to changing conditions, significantly reducing the risk of accidents on job sites.

Furthermore, automation in crane operations leads to significant cost savings and productivity boosts. The same MarketsandMarkets report indicates that automation can improve operational efficiency by up to 30%. Automated cranes can perform repetitive tasks with greater accuracy and speed, thereby minimizing human error and downtime. As sensors and machine learning algorithms become more sophisticated, these cranes will be able to predict maintenance needs, thus extending the lifespan of equipment and reducing unexpected failures. The convergence of AI and automation is setting new standards in the industry, ensuring that precision cranes not only meet but exceed the demands of modern construction projects for safety, efficiency, and reliability.

Sustainability Trends in Precision Crane Manufacturing and Usage

As sustainability becomes a priority across industries, the precision crane sector is not lagging behind. Manufacturers are increasingly adopting eco-friendly materials and production processes to minimize their environmental impact. Innovations in energy-efficient designs and automation technologies are enabling cranes to operate with reduced energy consumption, leading to lower carbon footprints and better resource management. This shift is not only beneficial for the planet but is also driving operational costs down for businesses that prioritize sustainable practices.

Tips: Consider investing in cranes that feature regenerative energy systems. These systems capture energy during operations, which can then be reused, enhancing overall efficiency and sustainability.

Another significant trend in precision cranes is the growing use of smart technology to monitor and manage cranes effectively. IoT devices and advanced monitoring systems provide real-time data, allowing operators to optimize crane performance while reducing waste. Remote diagnostics contribute to preventive maintenance, further enhancing longevity and reducing the need for materials and energy consumption associated with repairs and replacements.

Tips: Regularly audit your crane operations using data analytics tools. This will help identify areas for improvement in energy usage and operational efficiency, aligning with sustainability goals.

Related Posts

-

Exploring the Future: 2025's Largest Crane Innovations and Trends

-

Top 10 Tips for Effective Crane Lifting Techniques and Safety Best Practices

-

What is a Boom Crane? Understanding Its Types, Uses, and Benefits

-

7 Best Lifting Cranes for Efficient Heavy Lifting in 2023

-

How to Safely Operate a Wind Turbine Crane for Effective Installation

-

How to Safely Use a Crane for Lifting and Rigging in Construction